UVF – Universal Gear Milling Center

PRODUCT DESCRIPTION

The principle

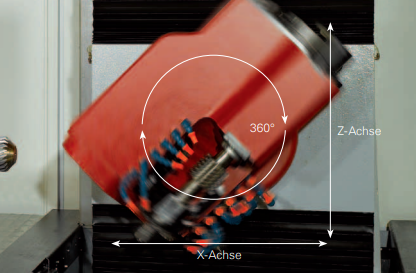

The Universal Gear Milling Center moves a stator in the X-direction and is equipped with a programmable, servo-motor driven B axis (milling head) with a tilt range of 360º.

The base machine is equipped in such a way to enable precision production with high availability.

Standard equipment includes a partial enclosure, direct position measuring systems for all axes except rotary axes, air-conditioned control cabinet, as well as a chip conveyor, a cooling lubricant filter system, and vibration-damping installation elements.

The basic machine: precise and robust

The machine bed of the Universal Gear Milling Center is a ribbed welded design.

The generously dimensioned, high-precision guides for linear axes X, Y and Z are centrally lubricated.

The guides of linear axes X, Y and Z are protected by covers.

Control: Innovative system platform

A 840D sl Siemens control with Sinamics-drives in a Rittal conditioning cabinet is used. The user-friendly User Interface guarantees easy and comfortable machine operations.

BENEFITS

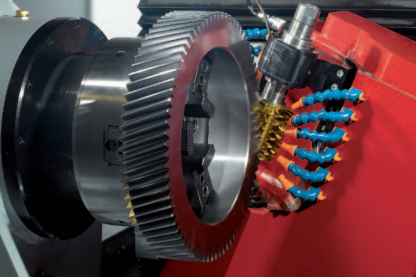

For gear cutting of

- Gear wheels

- Worms

- Worm wheels

- Spline shaft

- Trapezoidal thread spindles

- Timing belt pulleys

Highest dynamic

State-of-the-art linear drive technology ensures increased productivity.

Easy-to-use

With the sophisticated operating concept ergonomic handling and short training units are possible.

- Equipped for teleservice

- Special user interface for different gearing and workpieces types

Precise incremental measuring system

details and optional equipment

Fine filter system

With a 16kW cooling unit for emulsion.

Control / User interface

Siemens 840D sl with Sinamicsdrives in an air conditioned cabinet. Equipped for teleservice.

Workpiece formats

The machine allows you to handle workpieces up to Ø 1000 mm (UVF-Center III).

Optimal cooling

The full covering allows high quantity of cooling lubrictaion which enables a long tool service life.

Workpiece clamping

For optimum workpiece clamping we offer different diameter for the jaw chucks.

Bezel

The bezel supports long and slender components while processing and prevents bending and vibration.

Milling head with 360°

swivel range

The milling head with 360° swivel

range is CNC controlled and will

automatically clamped after reaching

the working position.

X-Axis: 1.200 mm / 2.200 mm /

3.200 mm / 4.200 mm

Z-Axis: 600 mm