FSM – Flat Grinding Machine

Product description

The principle

The FSM compact moves the machine table in the

X direction. (Table Machine). The basic machine includes

a range of equipment, which allows the machine to

use in high availability for the accurate production.

Standard features include:

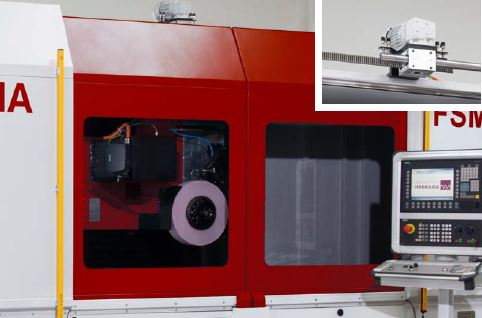

// Full encapsulation

// Direct measuring of the axes Y and W

// Emulsions mist filtration system

The basic machine

Das Maschinenbett der FSM ist eine verrippte Schweißkonstruktion.

Die großzügig dimensionierten, hochpräzisen

Profilschienenführungen der Achsen sind alle zentralgeschmiert.

VORTEILE

Hochstabile Konstruktion

Eine robuste Bauweise ermöglicht eine lange Haltbarkeit bei maximaler Präzision

Höchste Dynamik

Modernste Linearantriebstechnik ermöglicht ein Plus an Produktivität

Produktion Non-Stop

Vollautomatische Aufmaßermittlung

Easy-to-use

Ein durchdachtes Bedienkonzept ermöglicht ein ergonomisches Handling und kurze Schulungszeiten

DETAILS AND OPTIONAL EQUIPMENT

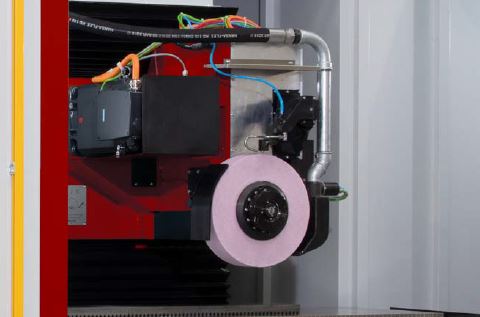

Grinding head with balancing system as standard

Fully automatic balancing system

which recognizes and removes

unbalances at a very early stage.

This guarantees a high quality of the

workpiece surfaces and a long tool

life of the spindle.

Dressing during production time by a 2-axis dressing system with diamond wheel

The grinding disk will be dressed

during production with a 2-axis CNC

controlled multigrain diamond dresser

which enables a consistently high

quality and less downtime.

Grinding disk change

The cylindrical grinding spindle allows

easy disc changing.

Coolant system

Coolant system with integrated fine

filter system, optional with 16 kW

cooling unit.

Generously dimensioned sliding doors

Optional also with automatic door

drive for comfortable and safe

working.

Control / User Interface

Siemens 840D sl with Sinamicsdrives

in an air-conditioned cabinet.

Equipped for teleservice.

Clamping devices (options)

Clamping device magnetic

Automatic adjustment of cooling agent supply (Option)

In case of wear the nozzle automatically

adjusts the diameter of the

grinding wheel.