ZSM compact – Rack Grinding Machine

PRODUCT DESCRIPTION

The principle

The rack grinding machine ZSM compact moves the machine table in the X direction (table machine). For helical racks, the grinding head slide to + / -30 degrees by manually pivoted. The basic machine includes a range of equipment, which allows the machine to use in high availability for the accurate production.

Standard features include:

- Full enclosures

- Direct measuring of the axes X + Z

- Anti-vibration mounting elements

The fixtures can be specified (see options), but they are not included in base price.

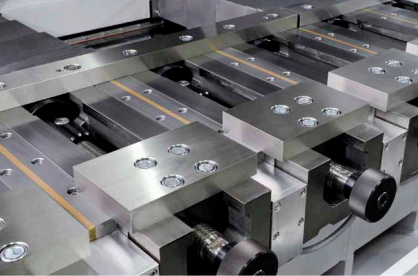

The basic machine: precise and robust

The machine bed of the rack grinding machine ZSM compact is a ribbed welded construction. The generously sized, high-precision linear guideways of the axes X, Y and the flat guideways of the X-axis are centrally lubricated.

Control: Innovative system platform

A Sinamics Siemens 840D sl with Sinamics Drive in a Rittal climate-controlles cabinet. Special user interface for milling teeth without NC programming

BENEFITS

The biggest advantage of our rack grinding machine lies in the price. With small downsides when it comes to comfort, you will get a machine precision as our PPSM-serie.

Solid construction

A robust construction provides a long life with maximum precision

High Dynamic

Modern linear drive technology enables increased productivity.

Standard automatik flanking

Easy-to-use

A sophisticated user interface allows ergonomic handling and short training time.

- Specific user interface for rack grinding without NC programming

Innovative details

Cylindrical grinding wheel adaptors guarantee a fast change of grinding wheels.

rack grinding machine: details and optional equipment

- working length: 2200 mm

- working length: 3200 mm

Display for helix angle

of C - Axis

Simple manual adjustment using an absolute encoder and an additional enlarged display.

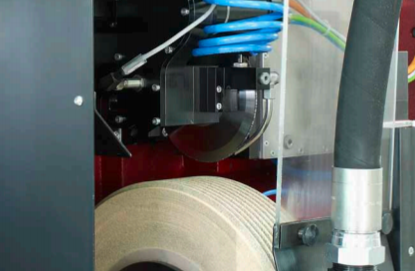

Grinding head with balancing system as standard

Fully automatic balancing system which recognizes and removes unbalances at a very early stage. This guarantees a high quality of the workpiece surfaces and a long tool life of the spindle.

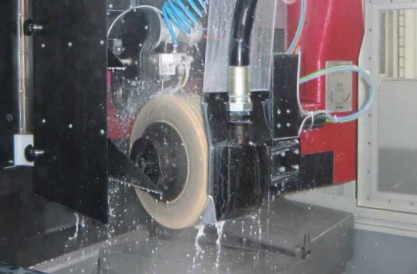

Dressing during production time by a 2-axis

dressing system with

diamond wheel

The grinding disk will be dressed during production with a 2-axis (3-axis = optional) CNC controlled diamond wheel which enables a consistently high quality and less downtime.

Automatic adjustment

of cooling agent supply

(Option)

The nozzle compensates abraison on the grinding disk automatically

Control / User Interface

Siemens 840D sl with Sinamicsdrives in an air conditioned cabinet. Equipped for teleservice.

Cooling unit

Cooling device with integrated deep bed filter.

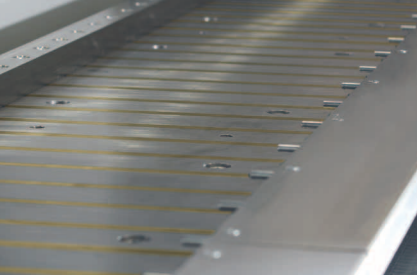

Magnetic clamping

with additional hydraulic

clamping (Option)

The magnetic plates draw the workpiece downwards for optimum support and the hydraulic clamping device clamps the workpiece.

Magnetic clamping

device (Option)

Electro-Permanent-Lifting Magnets 300 mm width.

Hybrid clamping device

(Option)

The magnetic plates draw the workpiece downward for optimum support and the hydraulic clamping device clamps the workpiece with up to 70 kN clamping force.