KPSM – contour precision grinding machine

PRODUCT DESCRIPTION

The principle

The KPSM moves the machine table in the X direction.With the help of our patented clamping device we are able to grin longitudinal profiles (cross-section up to 70 x 70 mm). This new innovation can grind two sides at right angles within one working cycle. Depending on the equipment, it offers the possibility of flatgrinding and profilegrinding up to 600 mm width. Standard features includes full encapsulation, direct measuring of the axes Y + Z, V and W, Coolant Fine Filter and anti-vibration mounting elements.

The basic machine

The machine bed of the FSM is a ribbed welded construction.

The generously sized, high-precision linear guide ways

are centrally lubricated.

BENEFITS

Highly rigid construction

The rigid construction guarantees a long lifespan combined with highest precision

Highest dynamic

State-of-the-art linear drive technology ensures increased productivity

Production Non-Stop

Fully automatic single flank

Easy-to-use

With the sophisticated operating concept ergonomic handling and short training units are possible

DETAILS AND OPTIONAL EQUIPMENT

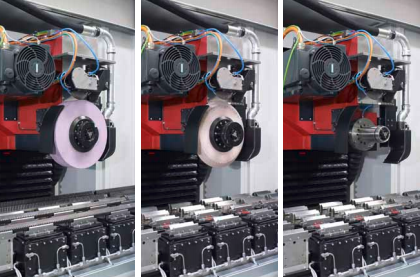

Dressing during production time by a dressing system with diamond wheel

The grinding disk will be dressed during production with a 2-axis CNC controlled diamond wheel which enables a consistently high quality and less downtime. The contours are freely programmable.

Grinding head with balancing system as standard

Fully automatic balancing system which recognizes and removes unbalances at a very early stage. This guarantees a high quality of the workpiece surfaces and a long tool life of the spindle.

Generously dimensioned sliding doors

Optional also with automatic door drive for comfortable and safe working.

Coolant system

Coolant system with integrated fine filter system, optional with 16 kW cooling unit.

Grinding disk change

The cylindrical grinding spindle allows easy disc changing.

Control / User Interface

Siemens 840D sl with Sinamicsdrives in an air-conditioned cabinet. Equipped for teleservice.

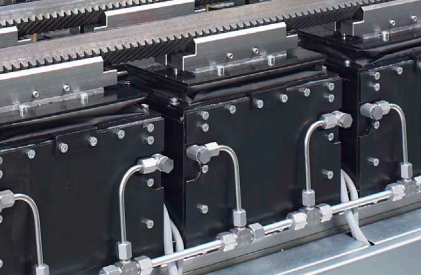

Special magnetic clamping device with additional hydraulic locking mechanism for torsion free clamping (Option)

Magnet will pull the working piece into ideal position and clamps it afterwards.

Automatic adjustment of cooling agent supply (Option)

The nozzle compensates abrasion on the grinding disk automatically.

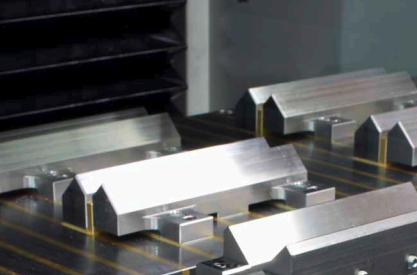

Special clamping device magnet plate with exchangeable prisms for torsion free clamping and grinding of rack and profiles in small series (Option)

The basic clamping device consist a magnetic plate. The additional prisms can be quickly installed and dismantled for small batches of racks. Without prisms, the machine can be used for flat grinding.