PPSM – High Precision Profile Grinding Machine

PRODUCT DESCRIPTION

The principle

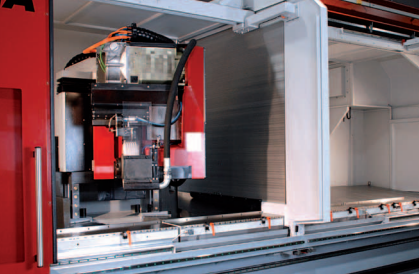

The high precision profile grinding machine moves a column in x-direction and works with a programmable servomotor-driven C-axis with a swivel area of –30° to +30° for helical gearings. The basic machine includes an range of equipment features that allows to use the machine in a very high level of machine availability for the precise production. Encapsulation, a position measuring system for all axes (apart from rotary axes), as well as a conditioned cabinet are equally important and therefore part of the standard version as well as chip conveyors, a filter system for the cooling agent and shock-absorbing elements.

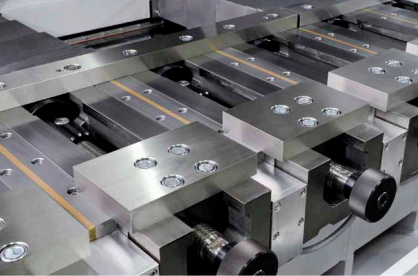

The basic machine: stable and dynamic

The machine bed of the travelling column machine is made of a ripped welded construction. The generously dimensioned guides consist of the linear axes X, Y, Z, W and U made of high-precision profile guides which are centrally lubricated. Heavy steel covers protect the guides of the linear X- and Y-axes.

Control: Innovative system platform

A 840D sl Siemens control with Sinamics-drives in a Rittal conditioning cabinet is used. The user-friendly User Interface guarantees easy and comfortable machine operations.

BENEFITS

Highly rigid construction

The rigid construction guarantees a long lifespan combined with highest precision.

Highest dynamic

State-of-the-art linear drive technology ensures increased productivity.

Non-stop production

- With the option “partition” the insertion can take place during primary processing time without any downtime

- Standard and fully automatic position determination

- Travelling column design for loading and unloading by hand, by crane or by handling system

Easy-to-use

With the sophisticated operating concept ergonomic handling and short training units are possible.

- Equipped for teleservice

- Special user interface for different gearing and workpieces types

Precise incremental measuring system

details and optional equipment

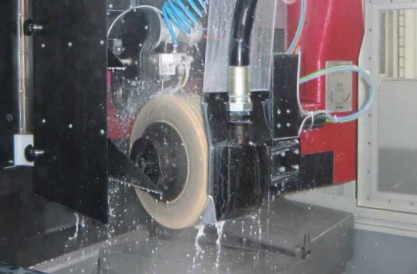

Cooling unit

Cooling device with integrated deep bed filter. Optional with 34 kW Coolant chiller.

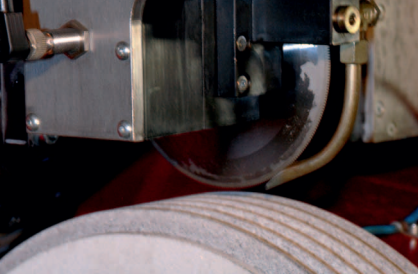

Dressing during primary processing time by freely programmable 3-axis-dressing unit with diamond contouring wheel

The dressing of the grinding wheel during the grinding process with a 3-axis CNC-controlled diamond wheel guarantees a constantly high quality and less downtime.

Grinding head with balancing system as standard

Fully automatic balancing system which recognizes and removes unbalances at a very early stage. This guarantees a high quality of the workpiece surfaces and a long tool life of the spindle.

Partition (Option)

From a working length of 4m the machine can be equipped with a fully automatic partition.

Automatic adjustment

of cooling agent supply

(Option)

The nozzle compensates abrasion on the grinding disk automatically.

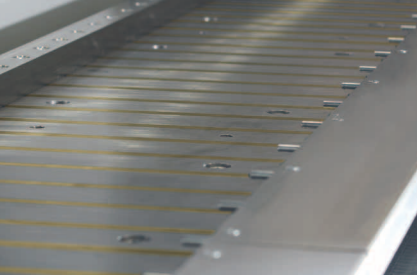

Magnetic clamping

device (Option)

Electro-Permanent-Lifting Magnets 300 mm width.

Magnetic clamping

with additional hydraulic

clamping (Option)

The magnetic plates draw the workpiece downwards for optimum support and the hydraulic clamping device clamps the workpiece.

Hybrid clamping device

(Option)

The magnetic plates draw the workpiece downward for optimum support and the hydraulic clamping device clamps the workpiece with up to 70 kN clamping force.