PPFM – High Precision Milling Machine

PRODUCT DESCRIPTION – PPFM

The principle

The precision profile milling machine moves a column in the X-direction and is equipped with a programmable, servo-motor driven C axis with a tilt range of -30º to +30º. The base machine is equipped in such a way to enable precision production with high availability. Partial enclosure, direct position measuring systems for all axes except rotary axes, and an air-conditioned control cabinet are just as necessary in our opinion and are therefore included as standard equipment, as are chip conveyors, a cooling lubricant filter system, and vibration-damping installation elements.

The basic machine: precise and robust

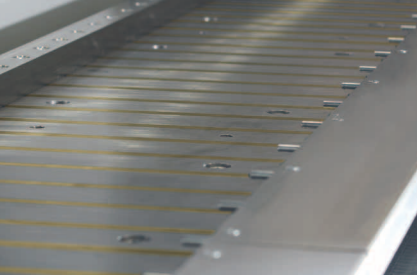

The machine bed of the moving-column machine is a ribbed welded design. The generously dimensioned guideways for linear axes X, Y, and Z are centrally lubricated. Solid steel covers protect the guideways of linear axes X and Y.

Control: Innovative system platform

A 840D sl Siemens control with Sinamics-drives in a Rittal conditioning cabinet is used. The user-friendly User Interface guarantees easy and comfortable machine operations.

BENEFITS

Non-stop production

Loading during primary processing time by pendular processing, optionally with partition.

Highest dynamic

State-of-the-art linear drive technology ensures increased productivity.

Precise incremental measuring system

Easy-to-use

With the sophisticated operating concept ergonomic handling and short training units are possible.

- Equipped for teleservice

- Special user interface for different gearing and workpieces types

details and optional equipme

Control / User interface

Siemens 840D sl with Sinamicsdrives in an air conditioned cabinet. Equipped for teleservice.

Milling tool change

Quick and simple milling tool change by a swiveling counter bearing.

Vertical spindle (Option)

Can also be fitted with a tool changer (for 10 tools).

Optimal cooling

The full covering allows high quantity of cooling lubrictaion which enables a long tool service life.

Fine filter system

(Option)

With a 13 kW cooling unit for emulsion.

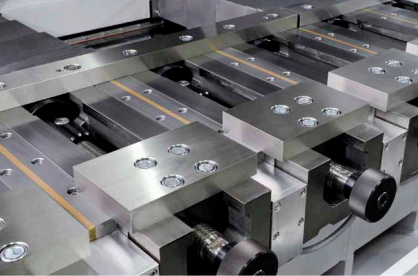

Magnetic clamping

with additional hydraulic

clamping (Option)

The magnetic plates draw the workpiece downwards for optimum support and the hydraulic clamping device clamps the workpiece.

Hydraulic clamping device (Option)

Gressel Gripo 160 with a clamping force of 70 kN max.

Hybrid clamping device

(Option)

The magnetic plates draw the workpiece downward for optimum support and the hydraulic clamping device clamps the workpiece with up to 70 kN clamping force.