ZFM compact – Rack milling machine

PRODUCT DESCRIPTION

The principle

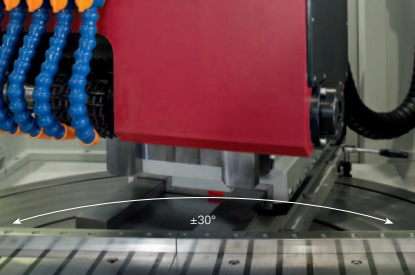

The ZFM compact moves the machine table in the X direction (table machine). For helical racks, the milling head slide to + / -30 degrees by manually pivoted. The basic machine includes a range of equipment, which allows the machine to use in high availability for the accurate production.

Standard features include:

- Partial enclosures

- Direct measuring of the axes X + Z

- Chip conveyor and anti-vibration mounting elements

The fixtures can be specified (see options), but they are not included in base price.

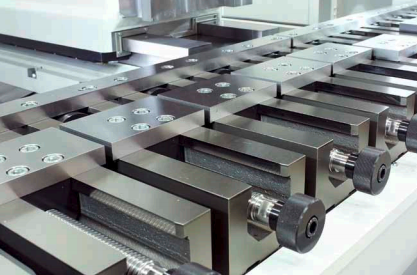

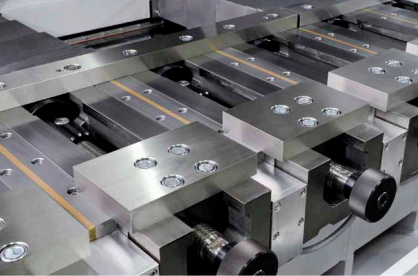

The basic machine: precise and robust

The machine bed of the ZFM compact is a ribbed welded construction. The generously sized, high-precision linear guideways of the axes X, Y and Z are centrally lubricated.

Control: Innovative system platform

A Sinamics Siemens 840D sl + touchpanel 10” with Sinamics Drive in a Rittal climate-controlled cabinet. Special user interface for milling teeth without NC programming.

BENEFITS

The biggest advantage of our machine lies in the price. With small downsides when it comes to comfort, you will get a machine precision as our PPFM-series.

High Dynamic

Modern linear drive technology enables increased productivity.

High performance with low space requirements

Easy-to-use

A sophisticated user interface allows ergonomic handling and short training time.

- Specific user interface for rack milling without NC programming

Precise incremental length measuring system

details and optional equipment

Fine filter system

(Option)

With a 13 kW cooling unit for emulsion.

Optimal cooling

The full covering allows high quantity of cooling lubrictaion which enables a long tool service life.

Display for helix angle

of C - Axis (Option)

Simple manual adjustment using an absolute encoder and an additional enlarged display.

Control / User Interface

Siemens 840D sl with Sinamicsdrives in an air conditioned cabinet. Equipped for teleservice.

Milling tool change

(Option)

Quick and simple milling tool change by a swiveling counter bearing.

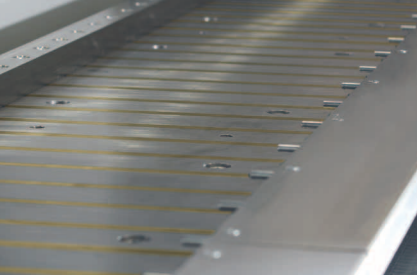

Magnetic clamping

with additional hydraulic

clamping (Option)

The magnetic plates draw the workpiece downwards for optimum support and the hydraulic clamping device clamps the workpiece.

Hydraulic clamping

device (Option)

Gressel Gripo 160 with a clamping force of 70 kN max.

Hybrid clamping device (Option)

The magnetic plates draw the workpiece downward for optimum support and the hydraulic clamping device clamps the workpiece with up to 70 kN clamping force.